|

|

|||||

|

|

|||||

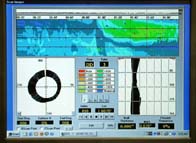

| The transducer transmits ultrasonic pulses though a rotating (1,800 rpm)

45° mirror and receives the pulses back from the inner and outer walls. A digital rotary B-scan displays the condition of inner and outer walls so that inspector can inspect the defects at a glance. |

|||||

| Outstanding Features |

|||||

|

(2.25") I.D boiler tubes |

|||||

| Application | |||||

|

|

|||||

|

|

|||||

| IRIS 9000 Version 3.08 | |||||

|

|

|||||

|

|

|||||

|

|

|||||

|

|

|

||||

|

|

|

||||

|

|

|||||

|

|

|||||

| |

|||||

| |

|||||

| Pre-treatment of tube before Inspection | |||||

|

|

|

||||

|

|

|||||

|

|||||

|

|

|||||

|

IRIS-9000 Software |

|

|